Sealing

Piston rings

With the development of the chemical industry, we have seen non-lubricated compressors for the chemical industry and those for automation increasingly used in recent years.The conventional piston rings (carbon rings, phenolic resin products) had often suffered abrasion due to gases.

When it comes to abrasion, our PTFE with a TRIFON filler has demonstrated all-time high performance while dependent on the environment such as pressures (loads), sliding speeds, sliding distances, lubrication conditions, counterpart metal materials, surface finish condition, temperatures. With its better high temperature properties than the conventional ring materials, this filled PTFE is profoundly resistant to instantaneous high temperatures and never suffer burning.

|

●Features 1. Sealing ensured with any fluid/gas 2. Low friction coefficient and excellent abrasion resistance 3. Possible use in wide range from -100°C to 220°C 4. Higher performance expected when combined with dissimilar materials 5. No damage even after sudden shock ●Performance Pressure: 10MPa Temperature: 220°C Speed: 4m/s ●Main applications Bucket rings for compressors, refrigerators, expanders, hydraulic cylinders and special fluid reciprocating pumps |

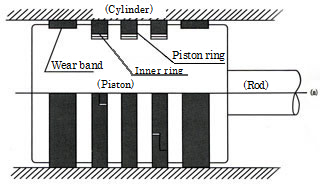

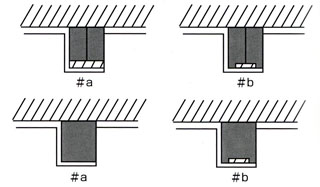

| Drawing of piston rings/wear bands | Drawing of piston ring installation | |

|---|---|---|

|

|

●Materials and applications

| Molybdenum disulfide +Glass fiber |

Bronze included | Glass fiber or Econol |

Carbon or Carbon fiber included |

|

| Color | Grayish black | Bronze black | Grayish white Yellow |

Black |

| App. | For air/gas | For high pressure | For oxygen | General gas Inactive gas |

| Char. | Low friction Low fever |

High PV value Small compressive strain |

Inactive Large extension |

High chemical- resistance |

◆To order our piston rings...

To design TRIFRON piston rings, we need to take thermal expansion into consideration.

Please make sure to inform us of the following items.

| 1. | Equipment types; names, vertical/horizontal | 6. | Piston materials and cylinder materials |

| 2. | Inlet pressure, outlet pressure | 7. | Detailed drawing of pistons and rods |

| 3. | Inlet temperature, outlet temperature | 8. | Rod materials |

| 4. | Piston and rod speed (or speed of rotation X stroke length) |

9. | Rod cooled or not |

| 5. | Fluid or gas names |